【ProAV Lab】Breakthrough - Smooth PTZ Movement

Written by Kieron Seth, Product Marketing Director at Lumens

August 04, 2022 38805

▶ Introduction

Compared with traditional cameras, a PTZ model is designed around a robotic mechanism which moves the camera head left and right (pan movement), and up and down (tilt movement). These movements mirror the normal movement of the human head, enabling the camera to produce a very realistic and natural look. With Lumens cameras, the head is designed to move smoothly and at variable speeds in each direction, and to work in tandem with the zoom lens to deliver lifelike results.

▶ How PTZ cameras work

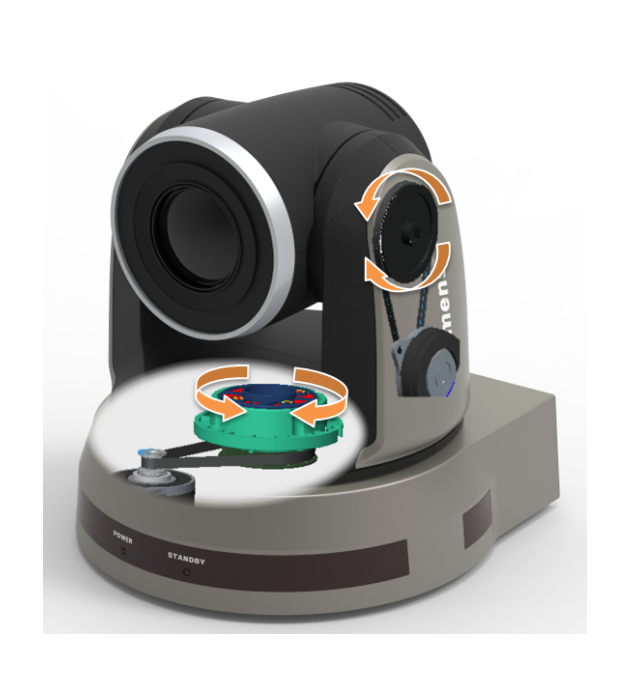

The PTZ camera is driven by dual motors, to rotate and move the head vertically. High-precision motors are used paired with a belt drive system to achieve precise positioning and variable speed movement.

▶ Challenges

• Positioning and Recovery Accuracy :

Cameras must return precisely to preset positions. Minor errors will accumulate, resulting in ever greater positioning inaccuracies.

• Variable Speed Motors :

A PTZ camera must have the flexibility to follow a fast-moving sport as well as the slow movement of a lecturer in a conference hall. It must also have the ability to move at high speed from one preset position to another. At low speed, the motion must be silky smooth, especially if the lens is gradually zooming in. In high-speed movements, the camera must reach its final position without any rebound or recoil.

• Considerations for silent operation :

PTZ cameras are designed to be low-profile and easy to mount inconspicuously. They must also be discreet in terms of mechanical noise, which must be minimal.

• Stability and reliability:

Stability and reliability are core requirements; durable materials and components must be selected to reduce wear and tear caused by the operation of the mechanism.

▶ Lumens solutions

Lumens uses three key technologies to achieve stable and reliable PTZ motion.

1. High Precision Hybrid Stepping Motors:

Lumens uses a (400 steps/rev) high-precision hybrid stepping motor. In addition to achieving high-precision positioning of 0.9″ in one step, it can deliver smooth motion and high-speed rotation.2. Curvilinear Belt Drive:

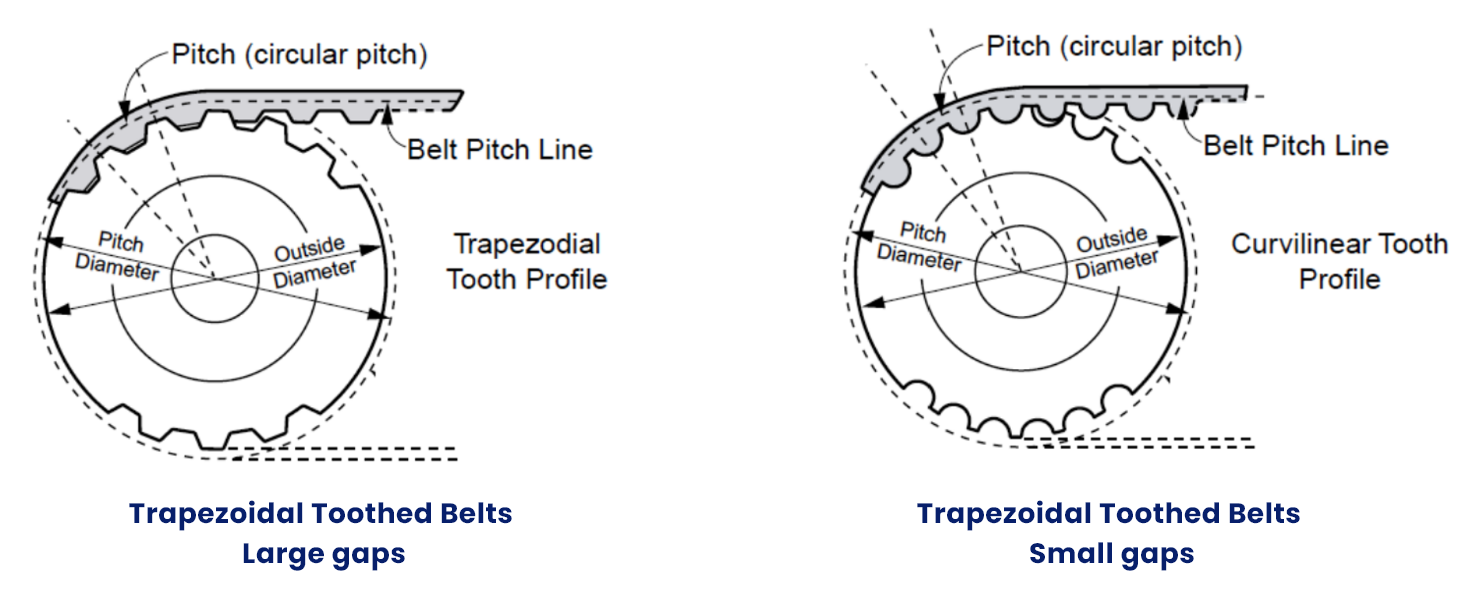

The curvilinear design of the belt drive keeps its teeth in close contact with the gear cog. The belt’s CR material is selected for its ability to effectively absorb vibrations and reduce noise.

3. Multi-speed Motor Controller:

Lumens employs S-shaped ramping in its motor drive. Designed to deliver micro-step changes in speed, this greatly reduces vibration during operation and delivers very refined camera movements. It maintains judder-free motion even at slow speeds, as well as perfectly smooth acceleration and deceleration.

.png)

▶ Video

Click here Back to Top ↑